[ 63XC.COM | HOW TO | 18 SPOKES ]

18 Spokes

I blame Jen Glick. Her famous Scorching for Starters hooked me on 63xc.com and the potential of offroad fixing. Several years ago I built up a KHS track frame as a street fixie, right after my last gearie tossed me into the windshield of a nice old lady's Toyota in the parking lot of my health club. (Sometimes I can take a hint.) I quickly reach the same conclusion as countless others. Fixies make the best urban bikes: quick, light, maneuverable, durable. But each bike of mine has to do double duty -- my track bike (Fixed Gear Gallery #2219) doubles as a road fixie -- so I think about doing something similar with my daily driver. Portland, Oregon, has filthy autumnal weather, hordes of mad cyclists, a fine selection of refreshing ales. We are the Belgium of North American cycling, so cyclocross is our penance of choice. Might the KHS have 'cross events in its future? A proper 'cross frame is designed with forks and stays to clear 35mm x 700c knobby tires, the race standard. But a track frame is built to much smaller clearances, so wheels will be the major problem... First commandment of wheelbuilding: thou shalt choose thy tires first! Hutchinson makes a very good 26 inch cross tire, and 26 inch slicks are fairly common on the street. Both clear fork and stays, so 26 inch (559 mm bead diameter) it is. Second commandment of wheelbuilding: thou shalt choose thy hub second! Not a problem for the rear, for there are many choices. But I need a brake for the front. No caliper brake will reach the 26 inch rim, and no track frame has mounts for cantilevers or discs. Looks like a drum brake is the only answer. I choose the SRAM VT5000, least dear of the lot, which comes only in 36h. Third commandment of wheelbuilding: thou shalt match thy rim to thy tire and thy hub! Here are the riches of the world. So many 26 inch rims exist that one can choose at will. I choose the Velocity Aeroheat because Dean Reed, my ace fix mechanic, stocks them in 36h, says they love spoke tension, and gives me 10% discount. Fourth commandment of wheelbuilding: thou shalt choose thy spokes, the pattern and the lengths thereof, with utmost care! Now Roger Musson is a cluey bloke. He is absolutely the best at explaining the whys and wherefores of spoking patterns, the tricky bits about measuring components, and the exasperating task of calculating spoke lengths to the accuracy necessary for any feasible design. Visit his web site from the sidebar for the best spoke length calculator. If you are smarter than I (i.e. can figure out PayPal) he will accept your money and dispense the indulgence of his entire sacred texts to your computer. At this point things get really fun. I could follow David Wrath-Sharman's elegant one-cross spoke design for a front hub-braked wheel, and do something normal, like two-cross, for my flip-flop rear. (This is smart, given that the braked front hub develops at least as much torque as the driven rear hub.) But why be normal? I long have admired wheels with low spoke counts. Might this be an opportunity to indulge myself? OK, but I'm stuck with 36h rims and hubs. So the only sexy low count feasible would be 18, half that. Roger to the rescue: normal designs must have some multiple of four spokes to balance forces; only the ancient crows foot will work for 18 spoke wheels, because 18 is a multiple of six. Crows foot it is, with spokes in alternate holes.

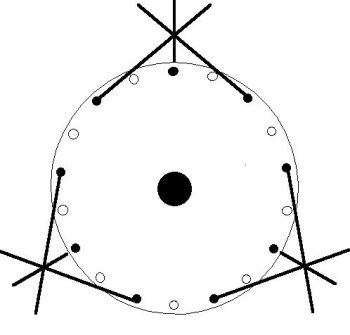

One side of 18 spoke crows foot lacing in 36 spoke hub. Radial spokes are short, angle 0°. Tangent spokes are long, nominal angle 80° -- actual angle as built is nearly 90° -- ideal. But are 18 enough? Spokes are made of high-alloy cold-worked steel wire, ultimate stress 150,000 pounds per square inch, so a single 2mm (14 gauge) spoke can support 700 pounds, the weight of a tandem and two very heavy riders! Of course, a working spoke must take other forces, namely the pre-tension (about 200-250 pounds) and the driving and braking forces (perhaps another 100 pounds). Deeper rims do tolerate fewer spokes. In theory one could build a wheel with eight spokes, but spoke tension would be extremely high and the rim would tend to wobble in use, even assuming it could be trued in the first place. Campagnolo's famous deep V Shamal was built with only twelve spokes for aerodynamic effect. Twelve seems to be the lowest practical number, but far beyond the skill and component set of the amateur. Noting that Velocity's catalog includes 650c rims like the 26 inch Aeroheat in 18 drilling, I conclude that 18 spokes will be adequate. I devise a spreadsheet accounting for all forces, and calculate that my crows foot 18 wheels will be radially strong and laterally stable with forces about equal those of Mr. Wrath-Sharman's one-cross 36 front.

SRAM VT5000 hub brake, Velocity Aeroheat rim, 18 spoke crowsfoot lacing. The critical force will come from braking torque. Only 12 of my 18 spokes can resist torque (6 of the 18 being radial in crows foot), but these lie nearly tangent to the hub and so take up the torque more effectively than the W-S one-cross, which lie nearer the radial. Hub brakes are big, and Mr. W-S himself says that big hubs are hard to lace. He's right. I use 2mm spokes, and the combination of big hub, stiff spokes and 26 inch rim make it almost impossible--I start from scratch three times! Truing isn't any easier, and after a day of thumpy riding I start that from scratch again too. The rear is not so hard, and results for both are pretty good. If I were doing it again, I'd use 1.8mm (15 gauge) spokes, which are plenty strong for my riding and easier to wrangle.

Hutchinson Cross Comp 559 mm by 35 mm tire does clear the KHS chainstays, but could use a half-link in the chain. I still worry about pedal clearance. The whole bike is now about 3/4 inch lower than it was, but the combination of 165mm cranks and high BB clears everything I encounter on the street. (But speed bumps in parking lots must be approached with great care.)The drum brake is smooth and progressive, with two bonus points: near-immunity from water, and tons of muck clearance at the fork. Plenty of miles on the slicks now, but few on the knobbies; we'll soon see how things work out in the mud. NEWS FLASH--MAD WHEELBUILDER CRASHES CONVERTED TRACK BIKE ON VERNONIA, OREGON, PATH. FINGERS DISLOCATED, LACERATED. CANNOT LIFT BICYCLE--CYCLOCROSS CAREER POSTPONED. So I take a tour by ambulance en route to five joyful hours in the emergency room. Laid up, I have a lot of time on my, uh, hands. I get out the calculator and gingerly press keys. (Ouch! Ouch!) I determine that, had I decelerated at one-half g, I would have toppled manageably over the bars. Instead, when my front wheel caught that tree root, the bike stopped instantly. I've seen plenty of rough stuff in 'cross races, but never a rider thrown over the bar to land sixteen feet down course. But Dean tells me that, aside from the skewed bar and the torn saddle, all is jolly well with the bike. The wheels are still true to his satisfaction. This wasn't the test I planned, but it does prove the wheelbuild a success. In the rough the KHS proves as quick, light, maneuverable, durable as on the smooth.

Jim's bikes can stand on their own! Jen said as much about scorchers to begin with. But then I learn that she too has encountered severe hand injury in the line of duty. No pain, no gain.

[ TOP ] |

Writer

James Bernard Lee, a renegade physicist, has for twenty-seven years tried to persuade the Acoustical Society of America to apply the Theory of Sound to the design of concert halls. He thanks the nice lady who sold him the fine Briko helmet that spared his life.

Date

v1.0 written November 2006

Related

Jen Glick's 'Scorching for Starters' is here.

Roger Musson's spoke calc is here.

David Wrath Sharman's hub brake wisdom is here.

Mailing list

Join the 63xc.com list.